Simulation Software

Use simulation software to model the stamping process, helping identify potential issues before production starts and allowing for adjustments to optimize the process.

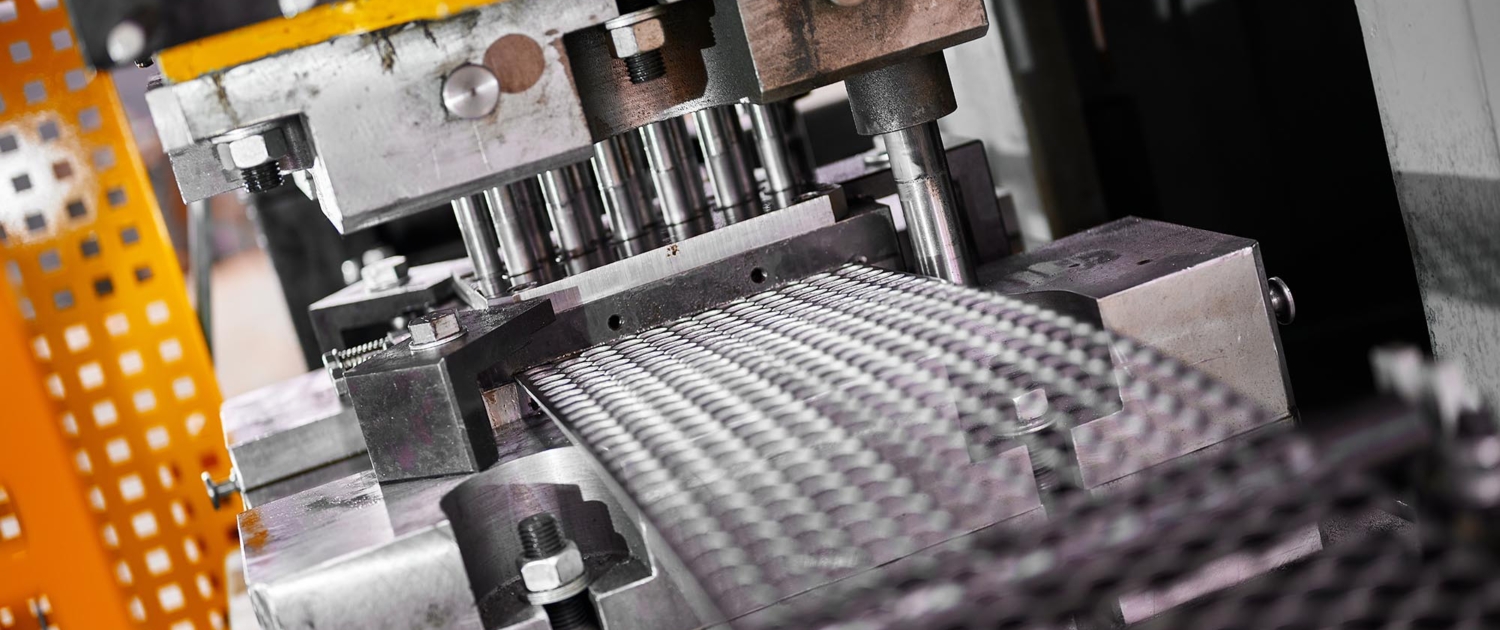

Metal stamping is a fundamental manufacturing process used to transform flat sheets of metal into a wide variety of products, from simple brackets to complex automotive components. While it offers numerous advantages, such as cost-effectiveness, precision, and scalability, it also presents its fair share of challenges. In this blog, we will explore some of the common challenges in metal stamping and discuss strategies for overcoming them.

Overcoming common challenges can significantly improve your company’s productivity and efficiency. Here are issues you may encounter during your precision metal stamping solutions:

Choosing the right material for metal stamping is crucial. The material’s properties, including its thickness, hardness, and ductility, can greatly affect the stamping process and the quality of the finished product.

Work closely with material suppliers and engineers to select the most suitable material for your specific application. Conduct material testing to ensure it meets your requirements.

The constant interaction between the metal sheet and the stamping die can cause wear and tear on the tools, resulting in reduced product quality and increased maintenance costs.

Regular maintenance and tool sharpening can extend the life of the stamping dies. Additionally, consider using tool coatings or materials that are more resistant to wear.

Poor die design or inadequate maintenance can lead to inconsistent parts and production downtime.

Invest in well-designed, high-quality dies, and establish a proactive maintenance schedule to address wear and damage promptly. Regularly inspect and clean dies to prevent issues.

Springback occurs when the stamped material returns to its original shape after being formed, resulting in inaccuracies in the final product.

Compensate for springback by over-bending the material slightly or using specialized tooling that accounts for this behavior.

Achieving tight tolerances and maintaining consistent product quality can be challenging, especially for complex parts.

Implement a robust quality control system that includes regular inspections, measurements, and statistical process control (SPC) techniques to monitor and improve product quality.

Certain metals are more prone to fracture and cracking during stamping, especially if they have a high strain hardening rate.

Adjust stamping parameters, such as temperature and pressure, to reduce the risk of material fracture. Preheating the material or using annealed sheets can help in some cases.

Material waste and scrap generation can be a costly aspect of metal stamping.

Implement efficient nesting and layout techniques to minimize scrap material. Consider recycling or repurposing scrap to reduce waste and environmental impact.

Acquiring and maintaining stamping equipment and tooling can be a significant investment.

Carefully evaluate your equipment needs and consider leasing or financing options to spread out costs. Develop a long-term strategy for equipment maintenance and replacement.

Balancing the need for high production speeds with maintaining quality and precision is an ongoing challenge.

Optimize stamping parameters, implement automation and robotics where possible, and continuously analyze and improve the production process to increase efficiency.

Metal stamping can involve hazardous materials, and there may be concerns about worker safety and environmental impact.

Implement safety protocols, provide appropriate protective equipment, and adhere to environmental regulations to ensure the well-being of your workers and minimize your environmental footprint.

Franklin Fastener has experience providing expert metal stamping solutions for multiple industries. Learn more about who we work with.

While the above solutions address many common challenges in metal stamping, some advanced techniques can further enhance the process’s efficiency and precision:

Use simulation software to model the stamping process, helping identify potential issues before production starts and allowing for adjustments to optimize the process.

Consider investing in servo-driven presses that offer better control over speed, force, and position, resulting in improved part quality and energy efficiency.

Utilize progressive dies for high-volume production. These dies perform multiple stamping operations in a single pass, reducing setup time and increasing production speed.

Implement sensors within the stamping dies to monitor various parameters in real-time, enabling quick adjustments and minimizing defects.

Apply lean manufacturing principles to reduce waste, improve efficiency, and streamline the production process.

Precision manufacturing solutions are vital for receiving components that are the right size and shape. Partnering with a reputable metal manufacturing provider is the best approach for getting the precise products you need.

Franklin Fastener utilizes the latest progressive die metal stamping technology to produce components that suit your needs. From concept to completion, our team leverages over seven decades of experience to develop products using the following capabilities:

At Franklin Fastener, we recognize that manufacturing in industries like heavy truck, automotive, and military relies on components that can withstand rigorous use. By collaborating closely with our customers, we design and supply optimized fasteners that keep their equipment running. Our commitment to service, innovation, and unparalleled quality builds lasting partnerships. The efficiency and value we provide have made us a trusted name in component manufacturing.

Contact us today to learn more about our precision metal stamping solutions.

https://franklinfastener.com/wp-content/uploads/2025/08/applications007-2.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2025-08-12 11:23:312026-02-27 09:50:11Clamp and Clip Failures: What Fastener Procurement Teams Overlook During Sourcing

https://franklinfastener.com/wp-content/uploads/2025/08/applications007-2.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2025-08-12 11:23:312026-02-27 09:50:11Clamp and Clip Failures: What Fastener Procurement Teams Overlook During Sourcing https://franklinfastener.com/wp-content/uploads/2025/06/Grommet-Assy_706-2-scaled.jpg

1236

2560

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2025-06-18 12:48:412026-02-27 09:50:11The Iso-Cush System: A Cushioned Clamp Designed for Noise Reduction and Durability

https://franklinfastener.com/wp-content/uploads/2025/06/Grommet-Assy_706-2-scaled.jpg

1236

2560

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2025-06-18 12:48:412026-02-27 09:50:11The Iso-Cush System: A Cushioned Clamp Designed for Noise Reduction and Durability https://franklinfastener.com/wp-content/uploads/2023/01/Ergo-Clamp™-product_.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2025-06-13 10:05:282026-02-27 09:50:11Ergo-Clamp: A Revolutionary Two-Piece Clamp Solution

https://franklinfastener.com/wp-content/uploads/2023/01/Ergo-Clamp™-product_.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2025-06-13 10:05:282026-02-27 09:50:11Ergo-Clamp: A Revolutionary Two-Piece Clamp SolutionFranklin Fastener is an industry-leading provider of engineered metal products. From concept to completion, our experts provide our clients with the highest service levels.

Improve Component Performance With These Metal Polishing Techniques

Improve Component Performance With These Metal Polishing TechniquesThis site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies.

AcceptLearn moreWe may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Google Webfont Settings:

Google Map Settings:

Google reCaptcha Settings:

Vimeo and Youtube video embeds: