The Hidden Engineering Between Industrial Clips and Clamps

Behind the scenes of every manufacturing system, there’s a host of small, unassuming components doing the heavy lifting, such as industrial clips and clamps.

Behind the scenes of every manufacturing system, there’s a host of small, unassuming components doing the heavy lifting, such as industrial clips and clamps.

These fasteners are often out of sight, out of mind—until they fail. And when they do, systems unravel, productivity grinds to a halt, and quality control starts ringing the alarm.

Take a closer look at why industrial clips and clamps deserve far more attention in the design and procurement conversation—and how the right design choices here can dramatically influence product performance, longevity, and efficiency.

Industrial clips are workhorses. They manage stress, support movement, absorb vibration, and maintain critical alignments. Whether they’re securing cables, positioning panels, or managing fluid lines, they’re doing so under constant load, exposure, and motion. Their job isn’t just to “keep things in place” but to do so reliably, under stress, and often without a second chance.

In critical applications like an aircraft cabin system or an automotive exhaust assembly, a clip that shifts half a millimeter can compromise fitment, generate vibration, or lead to long-term fatigue. Their engineering might be hidden, but their impact isn’t.

The key is recognizing that clips and clamps aren’t accessories but engineered elements of the full system. When they’re designed properly, they secure and perform.

Too often, clips and clamps are treated like off-the-shelf afterthoughts. But engineering-grade fasteners are anything but generic. Instead of simply finding a part that fits, checking the box, and moving on, their form, material, and fit determine how well they work.

This can be seen through:

The geometry of an industrial clip affects how load transfers through the system. A poorly shaped clip will concentrate force in one area, inviting fatigue or cracking. But a clip designed with distributed contact points and built-in flexing can absorb motion, redirect strain, and extend system life.

Mismatched materials can lead to galvanic corrosion, deformation under thermal stress, or unexpected creep. Selecting a stainless-steel clamp for an aluminum assembly might seem harmless—until you’re dealing with oxide buildup or structural degradation years down the line.

In many assemblies, fasteners aren’t installed once and forgotten. Instead, they’re removed for service or maintenance. Designing clamps and clips for repeatable engagement without loss of holding force ensures serviceability doesn’t become a liability.

The industries that rely most heavily on industrial clips are sectors where failure isn’t an option. Some of the biggest recipients include:

From brake lines to under-hood wiring harnesses, industrial clips hold the physical nervous system of a vehicle in place. They must endure temperature extremes, vibration, humidity, and exposure to road debris, all while keeping components aligned and free from damage. Clips that fail here can cause squeaks, electrical faults, or full-on mechanical failure.

In aerospace, every gram counts. That means clips and clamps must be lightweight, but never flimsy. They’re used in cabin interiors, hydraulic systems, and avionics housings. Reliability under vibration and pressure cycling is non-negotiable. Here, fasteners are engineered to exact aerospace standards for a reason.

Surgical tools and diagnostic equipment may rely on small, highly specialized clips for component retention, cable management, or shielding. These fasteners must be biocompatible, precision-formed, and often capable of withstanding aggressive sterilization cycles without deformation or corrosion.

Heavy-duty clamps and clips are used in everything from HVAC systems to cable trays and piping supports. They absorb movement, minimize vibration, and maintain integrity under dynamic loads. In this world, ruggedness is key, but so is precision. A misaligned bracket can lead to premature wear or structural instability.

From massive suspension bridges to intricate machinery, fasteners play a vital role in maintaining structural integrity. Learn more about their role in product assembly.

As product systems become more compact, complex, and performance-driven, so must the components that hold them together. Modern industrial clips are a far cry from the generic brackets of decades past.

Here’s why:

One of the most overlooked aspects of industrial clip design is how force distributes across a surface or joint. A clip designed with engineered flex can absorb and dampen that energy.

To best understand, imagine a bracket securing a fuel line. If the clamp concentrates all its force in a narrow contact area, over time, that region becomes a point of failure—fatigue, stress corrosion, cracking. But if the clamp is contoured, and its profile spreads the load across a wider footprint, the system becomes more resilient.

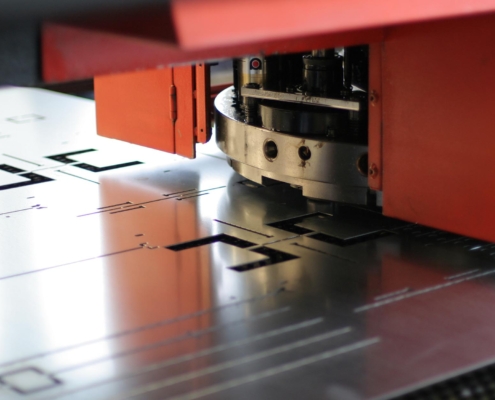

High-speed, multi-slide stamping machines, like the four-slide and progressive die setups we rely on, allow for more intricate geometries and stronger parts with tighter tolerances. These aren’t just stamped strips; they’re engineered structures.

For applications that demand weight savings and corrosion resistance, modern fasteners now incorporate high-performance plastics, elastomers, and hybrid composites. These materials can absorb shock, reduce rattle, and still maintain form under thermal cycling.

In specialized fields, we’re seeing clips embedded with strain gauges, RFID tags, or conductive pathways for grounding or signal continuity. These integrations allow manufacturers to track wear, manage predictive maintenance, and support smarter, more connected systems.

Industrial clips can be made from stainless steel, aluminum, spring steel, or plastic, but how it’s made matters just as much as the material.

Has it been spring-tempered? Heat-treated? Coated? Plated? Passivated? Each material decision impacts fatigue strength, corrosion resistance, elasticity, and cost. And no single choice fits every use case.

For instance:

More than window dressing, material science is baked into clip performance.

In the end, the value of industrial clips and clamps isn’t in their cost, but what they prevent.

They prevent misalignment, rattles, and failure while holding together wiring, piping, casings, housings, and systems. These fasteners do it under pressure, in motion, and often without notice. And they do it best when they’re engineered, not assumed.

When manufacturers take the time to source the right clips and clamps (designed for the application, built for durability, and installed with purpose), they don’t just improve the assembly. They improve performance, reliability, and even brand perception.

At Franklin Fastener, we’ve spent decades designing and manufacturing engineered clips and clamps for demanding industries. We don’t just stamp parts—we build solutions that keep systems together and operations moving.

From four-slide stamped brackets to cushioned clamps and coated assemblies, we provide fastening systems built for precision, repeatability, and performance. Whether you need standard parts or custom-built components, we’re here to help you get it right the first time—and every time after.

Reach out today to explore how our industrial clips and clamps can elevate your equipment, streamline your assembly process, and extend your product life.

https://franklinfastener.com/wp-content/uploads/2025/04/Franklin-Fastener-Captivated-Clamp-2.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2025-04-25 13:50:012026-02-02 09:50:01How to Choose the Right Clip or Clamp Industrial Fasteners for Your Application

https://franklinfastener.com/wp-content/uploads/2025/04/Franklin-Fastener-Captivated-Clamp-2.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2025-04-25 13:50:012026-02-02 09:50:01How to Choose the Right Clip or Clamp Industrial Fasteners for Your Application https://franklinfastener.com/wp-content/uploads/2025/04/How-the-Right-Fastening-Solutions-Reduce-Production-Costs.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2025-04-25 11:01:232026-02-02 09:50:02How the Right Fastening Solutions Reduce Production Costs

https://franklinfastener.com/wp-content/uploads/2025/04/How-the-Right-Fastening-Solutions-Reduce-Production-Costs.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2025-04-25 11:01:232026-02-02 09:50:02How the Right Fastening Solutions Reduce Production Costs https://franklinfastener.com/wp-content/uploads/2023/10/Metal-Stamping-Machine.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2023-10-17 09:00:002026-02-02 09:50:07Common metal stamping defects and how to avoid them

https://franklinfastener.com/wp-content/uploads/2023/10/Metal-Stamping-Machine.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2023-10-17 09:00:002026-02-02 09:50:07Common metal stamping defects and how to avoid them https://franklinfastener.com/wp-content/uploads/2023/01/Side-view-of-the-engine-with-a-special-tool-installed-to-adjust-the-valve-clearance.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2023-07-10 09:00:002026-02-02 09:50:07How to Improve Productivity in Manufacturing

https://franklinfastener.com/wp-content/uploads/2023/01/Side-view-of-the-engine-with-a-special-tool-installed-to-adjust-the-valve-clearance.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/12/fastener-logo1-01.png

Abstrakt Marketing2023-07-10 09:00:002026-02-02 09:50:07How to Improve Productivity in ManufacturingFranklin Fastener is an industry-leading provider of engineered metal products. From concept to completion, our experts provide our clients with the highest service levels.

How the Right Fastening Solutions Reduce Production Costs

How the Right Fastening Solutions Reduce Production CostsThis site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies.

AcceptLearn moreWe may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Google Webfont Settings:

Google Map Settings:

Google reCaptcha Settings:

Vimeo and Youtube video embeds: