Managing costs during product development is a perpetual challenge for businesses. Prototype wire forming offers significant cost advantages over traditional manufacturing techniques.

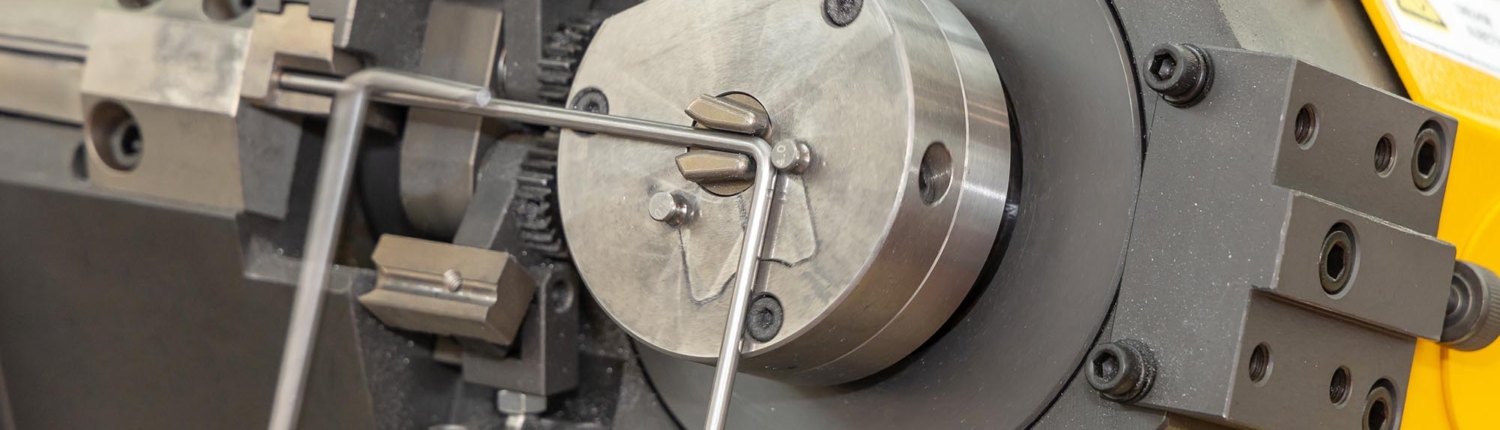

One key cost-saving factor is the elimination of expensive tooling and molds. Traditional manufacturing often necessitates the creation of molds, which can be costly, time-consuming, and may require adjustments. In contrast, wire forming relies on digital designs and CNC machines, which significantly reduces setup costs.

Moreover, the efficiency of the wire-forming process minimizes material waste. Mistakes or design changes can lead to discarded materials and increased costs with traditional methods. Wire forming allows for quicker design adjustments, reducing material waste and associated expenses.